Transmission leasing

65

for sale

11318

See all photos (9)

DAF DIV. AANDRIJFASSEN VOOR LF, CF EN XF

Propeller shaft for Truck

Used

Netherlands, BURGEMEESTER SLOBLAAN 00047 C 4231AA MEERKERK, The Netherlands

Published: 6dReference number 2370921

Ask for price

Used

Netherlands, BURGEMEESTER SLOBLAAN 00047 C 4231AA MEERKERK, The Netherlands

Contact the seller

Serbatoio Aria, barra accoppiamento, differenziale DAF

Differential gear for Truck

Replaces OEM: 106058, 1807596, 1892657

Used

Italy, Montoro

Published: 30dReference number 21206

Ask for price

Replaces OEM: 106058, 1807596, 1892657

Used

Italy, Montoro

Contact the seller

Albero trasmissione DAF

Propeller shaft for Truck

Replaces OEM: 1807596, 1693978

Used

Italy, Montoro

Published: 30dReference number 21173

Ask for price

Replaces OEM: 1807596, 1693978

Used

Italy, Montoro

Contact the seller

See all photos (6)

SPICER Lastschaltgetriebe Powershift transmissi

Transmission for Truck

20155300 km

Used

Germany, Marshallstrasse 20, 52146 Wuerselen, Germany

Published: 1mo 18d

4 999EUR

Price excl. VAT

- ≈ 5 820 USD

- ≈ 4 311 GBP

20155300 km

Used

Germany, Marshallstrasse 20, 52146 Wuerselen, Germany

Contact the seller

Kalmar R32822-630

Transmission for Material handling equipment

Used

Denmark, Jernaldervej 100, 8300 Odder

Published: 1mo 22dReference number 0156

Ask for price

Used

Denmark, Jernaldervej 100, 8300 Odder

Contact the seller

Dana TE10

Transmission for Material handling equipment

Used

Denmark, Jernaldervej 100, 8300 Odder

Published: 1mo 22dReference number 0135

Ask for price

Used

Denmark, Jernaldervej 100, 8300 Odder

Contact the seller

See all photos (10)

CASE Torque Converter 87712647 84357989 for CASE Wheel Loader

Transmission for Wheel loader

New2025Suitable for models: CASE WHEEL LOADER

New

China, 24th Floor Tianzhi Building, Qingdao Free Trade Zone

Published: 1mo 23d

Ask for price

New2025Suitable for models: CASE WHEEL LOADER

New

China, 24th Floor Tianzhi Building, Qingdao Free Trade Zone

Contact the seller

OCEANUS OC-800MB Controller for Loader

Transmission for Wheel loader

New2025Suitable for models: China wheel loaders

New

China, 24th Floor Tianzhi Building, Qingdao Free Trade Zone

Published: 2mo 16d

Ask for price

New2025Suitable for models: China wheel loaders

New

China, 24th Floor Tianzhi Building, Qingdao Free Trade Zone

Contact the seller

Dana 13.9TE10313-20

Transmission for Material handling equipment

2007

Used

Denmark, Jernaldervej 100, 8300 Odder

Published: 2mo 24dReference number 0130

Ask for price

2007

Used

Denmark, Jernaldervej 100, 8300 Odder

Contact the seller

ZF 6WG211

Transmission for Material handling equipment

2011

Used

Denmark, Jernaldervej 100, 8300 Odder

Published: 2mo 24dReference number 0125

Ask for price

2011

Used

Denmark, Jernaldervej 100, 8300 Odder

Contact the seller

Dana 1204FT20213-100

Transmission for Material handling equipment

2005

Used

Denmark, Jernaldervej 100, 8300 Odder

Published: 2mo 24dReference number 0106

Ask for price

2005

Used

Denmark, Jernaldervej 100, 8300 Odder

Contact the seller

ZF 3WG161

Transmission for Material handling equipment

Used

Denmark, Jernaldervej 100, 8300 Odder

Published: 2mo 24dReference number 0139

Ask for price

Used

Denmark, Jernaldervej 100, 8300 Odder

Contact the seller

Dana 13.9TE10313-25

Transmission for Material handling equipment

2009

Used

Denmark, Jernaldervej 100, 8300 Odder

Published: 2mo 24dReference number 0136

Ask for price

2009

Used

Denmark, Jernaldervej 100, 8300 Odder

Contact the seller

Dana 15.7TE 32418-81

Transmission for Material handling equipment

2016

Used

Denmark, Jernaldervej 100, 8300 Odder

Published: 2mo 24dReference number 0132

Ask for price

2016

Used

Denmark, Jernaldervej 100, 8300 Odder

Contact the seller

Dana 13.9TE10319-25

Transmission for Material handling equipment

2008

Used

Denmark, Jernaldervej 100, 8300 Odder

Published: 2mo 24dReference number 0134

Ask for price

2008

Used

Denmark, Jernaldervej 100, 8300 Odder

Contact the seller

See all photos (5)

ZF 3WG161

Transmission for Material handling equipment

Used

Denmark, Jernaldervej 100, 8300 Odder

Published: 2mo 24dReference number 0140

Ask for price

Used

Denmark, Jernaldervej 100, 8300 Odder

Contact the seller

Dana 340TE17313-40

Transmission for Material handling equipment

2009

Used

Denmark, Jernaldervej 100, 8300 Odder

Published: 2mo 24dReference number 0155

Ask for price

2009

Used

Denmark, Jernaldervej 100, 8300 Odder

Contact the seller

Dana 15.7TE 32418-81

Transmission for Material handling equipment

2014

Used

Denmark, Jernaldervej 100, 8300 Odder

Published: 2mo 24dReference number 0153

Ask for price

2014

Used

Denmark, Jernaldervej 100, 8300 Odder

Contact the seller

See all photos (8)

Volvo MS17X.- 2.85/ 3.08 .\5.29\ 5.63. Volvo FH12\ FH-13 truck

Differential gear for Truck

2003Suitable for models: Volvo FH12\ FH-13 truckReplaces OEM: 2071447 / 20836784. 20365667. 020113233115 MS17X A3 3200U2153 2.85 3190332 A33200U2153285 show all, 20055130235 A3 3200U2153285

Used

Estonia, Tallinn

Published: 2mo 25d

Ask for price

2003Suitable for models: Volvo FH12\ FH-13 truckReplaces OEM: 2071447 / 20836784. 20365667. 020113233115 MS17X A3 3200U2153 2.85 3190332 A33200U2153285 show all, 20055130235 A3 3200U2153285

Used

Estonia, Tallinn

Contact the seller

See all photos (15)

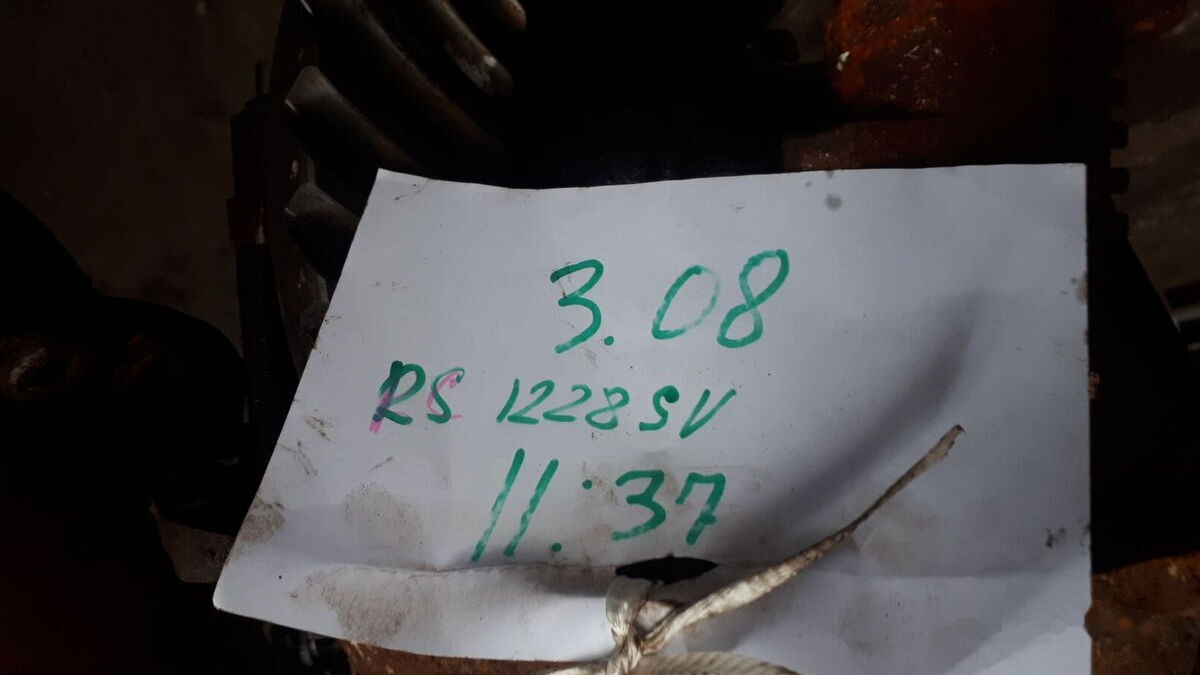

Volvo S91\PP .R9S . A-132 .RSS-1228B . RS1228SV. RS-1228C. RSS1344C. E Volvo B7R

Differential gear for Bus

2005Suitable for models: Volvo B7RReplaces OEM: S91\PP -637103. 4460091225. R9S .-620628. 4415101091. 3190332 20055130235 70313921 3152170 20789612 . 1523612 703139279 . 21296161 . 20836784. 2071448 20714478 . 9957685 .20836784 . 3152173. A52200621232. A3200U2153 20874634 21669014 20874633 22296580 20864048 21652491 EV90\3.10- 1671875. 128472 E show all, RSS1344B . 3.08 .RSS1344C -2.64/. 2054338. 20480739 RS1228SV - 2.85 /3.08.\ 3.70. RS-1228 C -5.63.\. RS-1228B 2.85.\ 3.08.\3.37.\3.7.\4.11.\5.29.\5.63/ A132 4474035358 -4.70 / 5.22 EV -85/-3.56 B7R ./ 3.78.\ 4.25 \ 4.87.\ 5.43/ Eaton show all

Used

Estonia, Kohtla-Jarve

Published: 2mo 25d

Ask for price

2005Suitable for models: Volvo B7RReplaces OEM: S91\PP -637103. 4460091225. R9S .-620628. 4415101091. 3190332 20055130235 70313921 3152170 20789612 . 1523612 703139279 . 21296161 . 20836784. 2071448 20714478 . 9957685 .20836784 . 3152173. A52200621232. A3200U2153 20874634 21669014 20874633 22296580 20864048 21652491 EV90\3.10- 1671875. 128472 E show all, RSS1344B . 3.08 .RSS1344C -2.64/. 2054338. 20480739 RS1228SV - 2.85 /3.08.\ 3.70. RS-1228 C -5.63.\. RS-1228B 2.85.\ 3.08.\3.37.\3.7.\4.11.\5.29.\5.63/ A132 4474035358 -4.70 / 5.22 EV -85/-3.56 B7R ./ 3.78.\ 4.25 \ 4.87.\ 5.43/ Eaton show all

Used

Estonia, Kohtla-Jarve

Contact the seller

T1 new listing page - Transmission leasing